Medical Equipment Transportation – MRI System

After five months of planning, the project was executed within just five days

The Brief

A market leading provider of medical imaging equipment required a specialist transportation company to assist in offloading a new MRI System from third-party transport at University College London Hospital (UCLH). This requirement presented several challenging tasks for medical equipment movers as the system was needed within the lower basement of the central London site.

The Response

As standard, Flegg Projects representatives thoroughly assess sites for all possible outcomes before making suitable suggestions that consider factors such as accessibility, time and costs. For the MRI System, a Project Manager attended UCLH to meet with various stakeholders and outline the key issues preventing a straight-forward installation. It was identified the route to the basement was via a ventilation shaft. Initial detailed safety documents including a risk assessment, method statement, lifting plan and drawings were provided. Additional visits would also be made before delivery to ensure success and the implementation of all final arrangements.

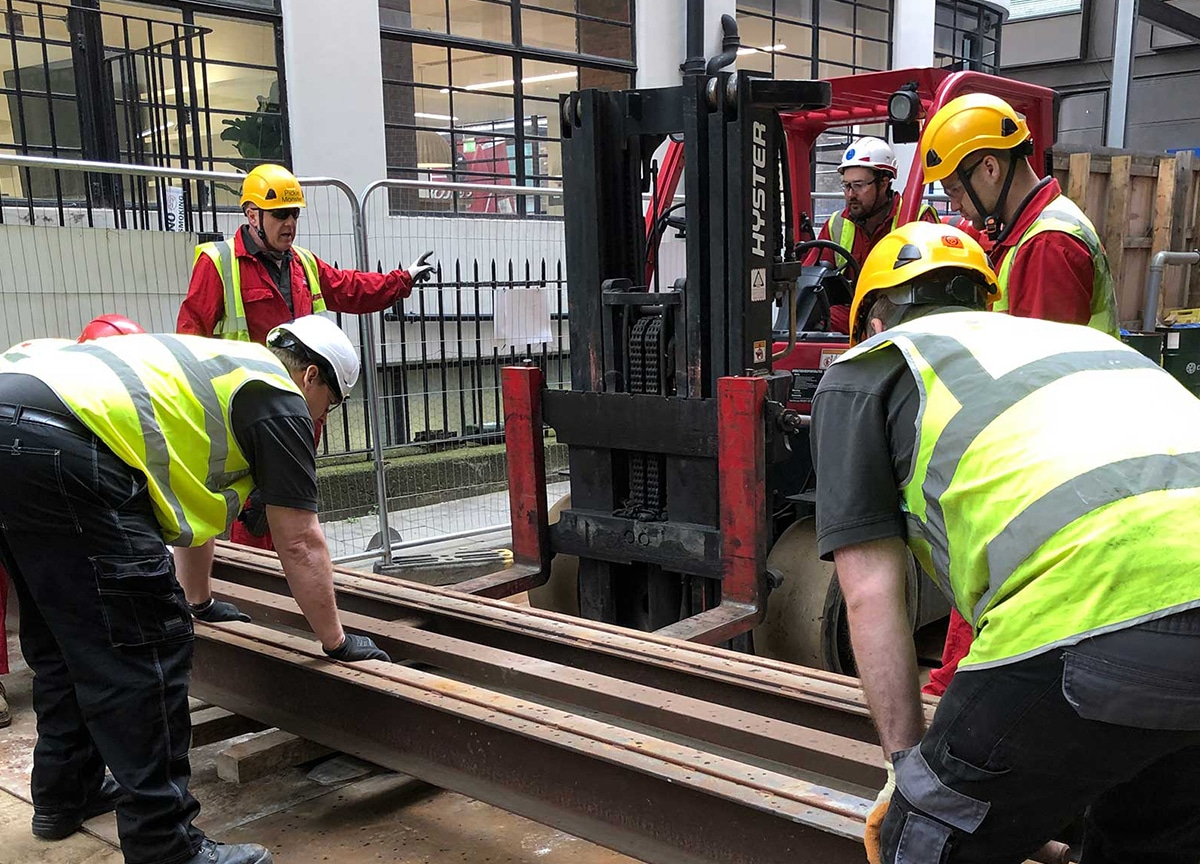

Flegg Projects ensure the latest and most up-to-date equipment is available for jobs of this nature. An Enerpac 60T hydraulic lifting system, 40/60 Hoist LPG forklift, Hyster S7 LPG forklift, steel road plates, air-hoist, compressor and standard lifting tackle were all identified and made accessible. All lifting equipment and crew would be provided by Flegg Projects, as would handling the road closures required for work to be completed over a 5-day period.

The Result

Applications for road closures were made 12-weeks prior to the job being undertaken and final safety documents was submitted promptly including the necessary training and inspection records. Due to the ventilation shaft route previously identified, a specific approach was utilised to complete the lift safely without compromising the structure of the building.

The 40/60 forklift truck offloaded the main units and carried these to the building entrance, before the 60T hydraulic gantry was used to move them into the building via the first opening and riser. From here, the units were lowered onto a temporary platform and an air-hoist was attached to re-configured lifting points, with safety beams positioned below prior to suspension. The platform was then struck down, leaving a clear void below for each part to be lowered into the basement. Finally, transport wheels were fitted and the MRI System was successfully transported to the appropriate location.

After approximately 5 months planning, the project was successfully executed over a specified 5-day period within the timetable set out.

The expertise you expect

The expertise you expect