The complexities of an international factory relocation

Considering an international factory location in today’s climate can feel insurmountable.

Brexit, inflation, supply chain disruption and the Russo-Ukrainian war have caused a cascade of operational and logistical challenges. All of these can exacerbate the existing complexities of an international factory relocation.

For businesses wanting to relocate, the question is, is it worth the cost, the time, and the upheaval?

Reasons for relocating

A business may be inclined to relocate for several reasons. An international relocation can bring numerous benefits to a business: access to new markets, a greater labour pool and tax benefits are just a few. For some companies, it’s a lucrative and effective business decision, signifying undeniable business growth or gaining momentum in new regions. On the other hand, relocation may stem from a different business need. The economic climate has forced some businesses to relocate their assets and factories in order to downsize resources and maintain operations or find efficiencies by combining multiple locations and assets into a single entity.

Either way, without professional expertise and guidance, the impact of inevitable complexities may weigh down on any potential profitability and cause further concern among stakeholders.

The complexities of an international factory relocation

Documentation

The complexities of an international factory location begin at documentation. Ensuring the relevant documents are correctly prepared can hugely reduce the likelihood of delays. Documentation varies of course depending on the desired location, or the type of equipment being relocated. Plus, language and cultural nuances can also play a part in complicating the documentation process, so expert advice can be instrumental in reducing the risk of errors, helping the entire process move more swiftly.

Machinery & packaging

Machinery also needs to meet customs regulations and restrictions. Medical equipment brings with it its own compliance consideration, and some countries (including Australia) expect any timber materials to be heat-treated to prevent the spread of diseases and insects. There is also the consideration of compliance regulations such as ISPM15 which is applicable to all export packaging. This must be taken seriously to reduce the risk of machinery becoming damaged, or even worse, lost in transit.

Communication

An international factory relocation often involves an increased number of stakeholders. This can further complicate people management and communication. Outlining who will be communicating the process to involved parties and ensuring consistent and clear communication is maintained is another essential component of an effective relocation.

Freight availability

Prices for freight have rocketed due to a lack of availability and increased demand. Some parts for new machinery are difficult to find which delays deliveries and can result in factories needing to run equipment which they had planned to replace. This can cause a knock-on effect of uncertainty and indecision around budgeting and CapEx matters.

Resource allocation and planning

Of course, there is also the alignment of all the resources required and ensuring all the relevant documents are prepared. Even with lots of planning, there is much more risk of vehicles being delayed due to customs. So, it’s important to work with freight movers that understand the implications of delays and the ability to flag these as soon as possible.

Work Visas

Whilst there are now difficulties with UK nationals fulfilling certain activities in the EU – the EU workers face similar difficulties with securing visas. This has affected lead times, availability and cost, making the fulfilment of many removals/installations much less predictable – on top of all the logistics issues created by Brexit and Covid.

Time critical

The time involved in a factory location can weigh heavily on the operational efficiency of a business. If the relocation impacts existing operations, there is downtime to be considered. Moving fast and swiftly is paramount to a successful international factory location. This can be managed by taking several precautionary measures.

But it can be done! We have worked with a client to get their machinery packed and loaded in just 7 days. Read the full case study here.

How we help

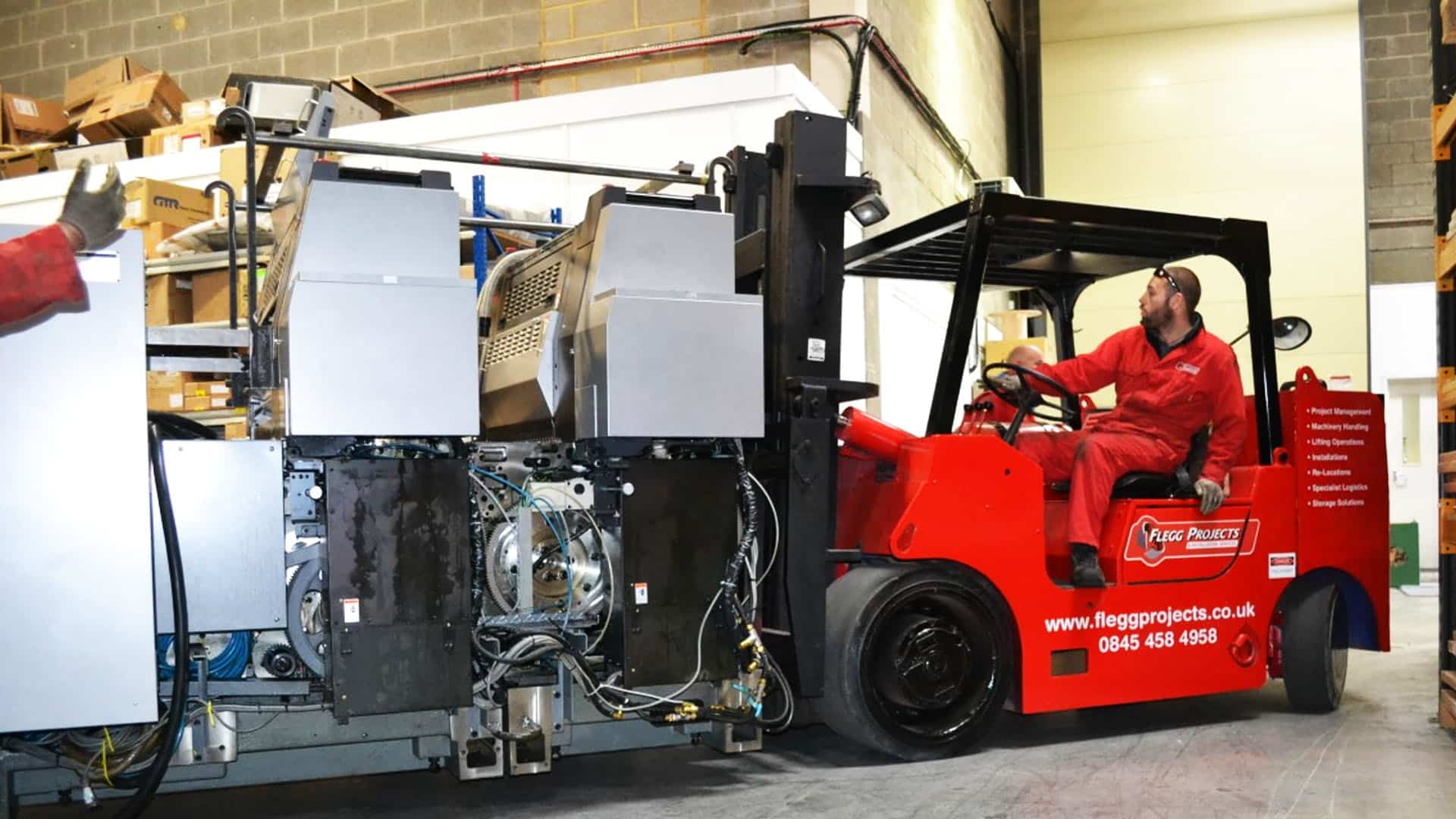

Flegg’s project team continues to collaborate with a team of trusted partners. All are armed with specific expertise in customs, transport, and shipping of specialist cargo. Coupled with our in-house experts and resources including machine movers and lifting equipment; Flegg is well-placed to provide a comprehensive relocation service for small/single machine movements or for organisations looking to locate complete sites or business units.

In the past 18 months, we have completed several significant international factory re-locations; it’s fair to say that fulfilment has been more difficult than ever before.

Flegg has a team of experienced and knowledgeable in-house engineers available to support machinery dismantling and assembly activities. We can provide a range of packaging solutions dependent on environmental factors and transit duration.

In the past, the process was relatively straightforward in terms of planning and logistics.

Once the assets had been identified and a programme agreed upon, it was a simple case of removing the equipment from the factory, securing it onto a vehicle for safe transit and tracking to destination. Depending on the scope, we may also have arranged to provide engineering or lifting support at the receiving site – with locations all around the globe.

Unprecedented economic and political disruption has put pressure on all corners of the machinery moving industry. But we do not take disruption lightly. With this adversity has come newfound confidence and knowledge in our abilities to deliver, despite inevitable complexity. Complexity has forced us to hone our skills, improve our services, and expand our offering to further support our customers and ensure their businesses emerge from the relocation unscathed and thriving.

If you are moving capital equipment in/out or within the UK please contact our sales team who will be happy to discuss supporting your successful project.

The expertise you expect

The expertise you expect